Increase your production 10%+

Picking the right OEE tool is more than just picking a counter and some software that records downtimes. The solution better have great analytical tools, a quick and easy way to collect and review your downtimes, and the ability to collect other vital information. The tool should also easily integrate into your existing control systems without causing a major quake in the normal order of operations. But also, the tool you use should incorporate the best-in-practice methodologies to get everyone on the same page and focused on getting your productivity to world-class levels.

Transform your Manufacturing Operations with PerformOEE™ a Smart Factory Software. PerformOEE™ and OEEsystems methodology will enable you to take control of your continuous improvement process.

Science of Manufacturing

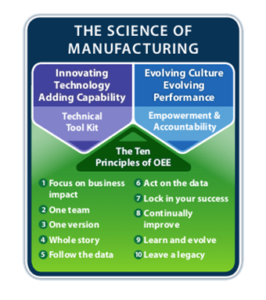

By using the Science of Manufacturing Methodology (SOM) by OEEsystems, everyone gets on the same page. The following illustration outlines the 10 SOM Principles of OEE:

These Proven Principles focus on people and culture, generating consistent quality and higher yields.

Follow the data – Knowing the true root causes of lost business opportunities, you can prioritize and ensure your people are always working on the most effective opportunities.

Lock In Your Gains – Continuous monitoring ensures gains are locked in, driving return on investment higher and faster, while our experience helps you implement the project and the necessary culture changes to truly empower your team.

PerformOEE™ Smart Factory Software

PerformOEE™ OEE Software solutions are being used by many world-class manufacturing companies. This software tool is designed to work in discrete, batch, or continuous processes no matter what industry. This software is optimized for use in operations on the shop floor as well as analytical tools that are uniquely tailored for senior management to make high-level decisions.

The concept is straightforward, give operations a one team, one mindset downtime management system, integrating manual and automatic data collection to one single data receptacle to easily analyze the information from the micro level to the macro level. Measure by product, size, shift, operating team, production line, production area, plant-wide, or enterprise-wide to easily follow the data and get the results you need to improve your productivity, your quality, and your yields.

Quick Implementation

The OEEsystems Team will work with your staff and a designated OEE champion to implement the system quickly. Our team will help with the discovery process to utilize your company’s tribal knowledge of the process. Together we will offer decades of manufacturing experience to implement PerformOEE™ with your specific downtime terminologies and collect data from your existing hardware and software to integrate the information into one system.

Implementation can be as fast as a few days to a few weeks.

Take Control of your Continuous Improvement

PerformOEE™ is suitable for all users within your business, from operators on the shop floor to those at the senior management level. Our Quality Compliance Checklists, Dashboards, and Reports are perfect for those operating in a regulatory environment. Smart Factory OEE Software, PerformOEE™, with their Science of Manufacturing Methodology delivers real-time visibility, analysis, and control of your manufacturing performance.

For more information, click here https://informatrac.com/software/oee/ or call (805) 456-4465

OEEsystems website: http://www.oeesystems.com

No Comments

Be the first to start a conversation